Have you ever heard of vapor blasting? If not get ready to discover a technique that can bring new life to your next project. Today, we’re going to delve into the details of vapor blasting and explore why it could be the best choice, for your restoration needs.

The Amazing Benefits of Vapor Blasting

Vapor blasting, also known as blasting or liquid honing, is a superhero in the world of surface preparation. It’s the go-to method for cleaning, finishing, or restoring materials. Let’s take a look at how it works!

1. Abrasive Media: Imagine combining materials like sand, glass beads or aluminum oxide with water to create a slurry. The choice of abrasive depends on the task at hand.

2. Water: Water plays a role, in this process as it controls dust cools down the particles, and protects delicate surfaces from any potential heat damage.

3. Pressure: Equipped with the slurry mixture a specialized machine pressurizes and sprays it onto the surface using a nozzle. You have the control, in your hands – adjust the pressure according to the demands of the job.

4. Optional Cleaning Agent: Sometimes we bring a cleaning agent to the party, which enhances the cleaning or degreasing abilities of the process.

The combination of particles and water provides a controlled action making vapor blasting excellent for cleaning removing paint and finishing surfaces. What makes it stand out? Its ability to achieve a finish without causing damage to materials.

Introducing Derek Fairley – The Master of Vapor Blasting

Anyone who dives into the world of vapor blasting at K.A. Sodders Painting will get to work with Derek Fairley – our extraordinary head blast technician since 2018. Derek is no stranger to blasting scenes; he began his blasting journey in 1992 at Atlantic Marine in Mobile, Alabama, and Ship Yard International along the Gulf Coast in Mississippi and Texas. As a highly trained certified blasting technician, Derek has worked on oil rigs, tugboats, cruise ships, industrial interiors, and exteriors well as commercial and residential buildings. You name it. He’s blasted it.

We caught up with Derek for a quick chat:

Q: Why do you prefer Vapor Blasting?

- Derek: “It’s the best. With dry blasting, you need to have a clear, isolated area due to the dust and airborne contaminants and you have to watch for heat damage from friction. With vapor basting the air pressure pushes out a mix of water and abrasive media. The mixture adds extra weight to the blast debris, carrying it to the ground quickly after being blasted – keeping the dust radiance down by 92%.”

Q: Why should people try vapor blasting?

- Derek: “Vapor blasting is more efficient. It’s cheaper and faster because there is less cleanup. But, most importantly – it’s safe. It’s environmentally friendly because it keeps the dust from going airborne and contaminating anything near the area. At K.A.Sodders we have serviced several Walmart Stores and sometimes we have to blast while the store is still open. Vapor blasting keeps the dust from getting on the customers, cars, on Walmart’s property – that sort of thing. That’s why we prefer to use it. It keeps people and things safer.

Q: What’s in the vapor blast mix?

- Derek: “It’s a combo of media – sand or crushed glass, depending on the job – and water The water not only prevents dust but also cleans better and more gently – preventing scratching or damaging. We use a special additive called “HoldTight” on metal to prevent flash rusting when we vapor blast.”

Q: Who’s the ideal customer for vapor blasting?

- Derek: “Anyone needing rust, corrosion, or paint removed. It’s for those who want to restore something to its original surface. No job’s too big or small!

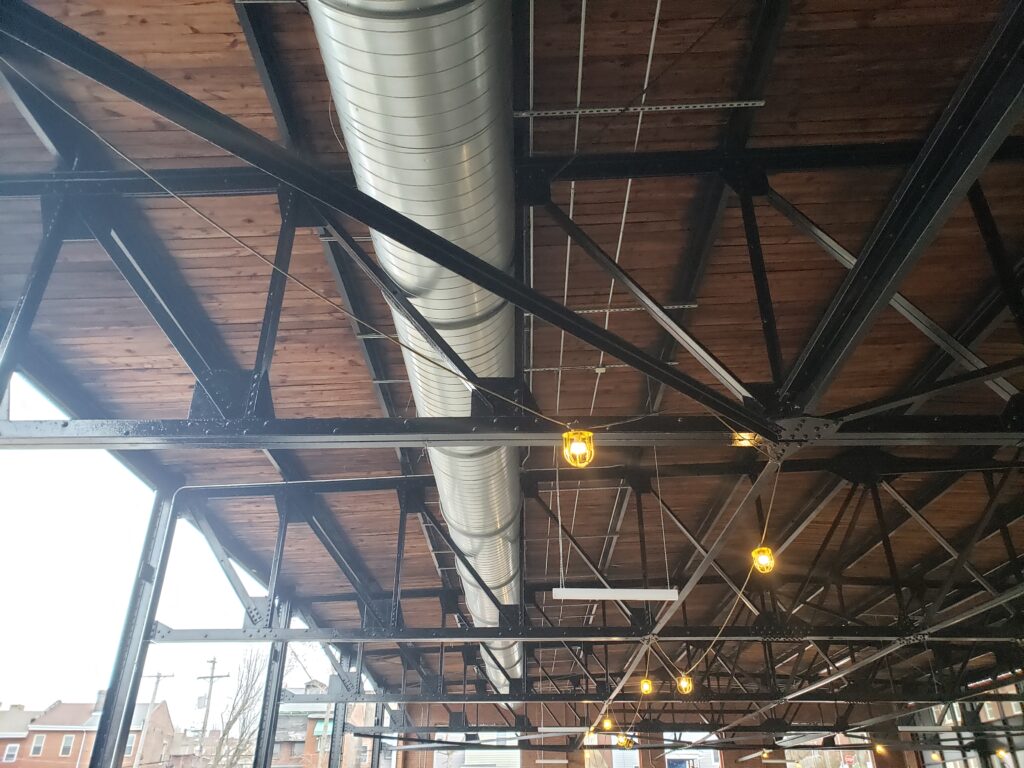

- On a large scale, K.A. Sodders once restored the exterior and interior of an old railroad building in Downtown Pittsburgh called the Mintwood Building. They had those old railroad ties going across the ceiling and brickwork that was painted over. We had to carefully remove the paint and mildew buildup to restore the original railroad ties and brick without disturbing any of the mortar and joints. This was a delicate process that required a qualified vapor blaster like myself. When we finished and brought it back to its original back color, it was beautiful!”

Cost Advantages of Vapor Blasting

1. Efficient Use of Resources:

Vapor blasting minimizes waste, making it a cost-effective solution. You’re not flushing money down the drain with unnecessary cleanup.

2. Time is Money:

The speed at which vapor blasting works means less labor time. Your project gets done quicker, saving you money on man-hours.

3. Versatility for Any Project:

Whether it’s a residential touch-up, a commercial overhaul, or an industrial restoration, vapor blasting adapts to the job at hand. One method, endless possibilities.

Vapor Blasting on Home Exteriors

1. Enhancing Metal Marvels (Railings and Fences):

Revitalize metal features by removing rust and revealing their shine.

2. Achieving Patio Perfection (Furniture):

Transform your weathered patio set into the envy of the neighborhood BBQ by using vapor blasting.

3. Creating Exterior Elegance (Walls and Surfaces):

Prepare your home for a coat of paint by vapor blasting the walls leaving them smooth and ready, for a makeover.

To sum it up, vapor blasting isn’t just a cleaning method; it’s a restoration wizard. With Derek Fairley at the helm, you’re in good hands. So, if you’re on a quest to revive your treasures and protect your surroundings, consider vapor blasting for your next project.

Happy blasting!